Services

4.0 IT Systems

End-to-end supply chain visibility, traceability and integrations

Real-time Actionable Data

From our early beginnings, we believed that the supply chain space would require more technology, tighter compliance, and greater flexibility.

After 20 years of constant development of our own proprietary IT systems, we bring efficiency and accuracy by being able to connect to any other system, operate in EDI/Non-EDI environments, and provide a growing suite of actionable data solutions firmly based on supplier generated barcode labeling.

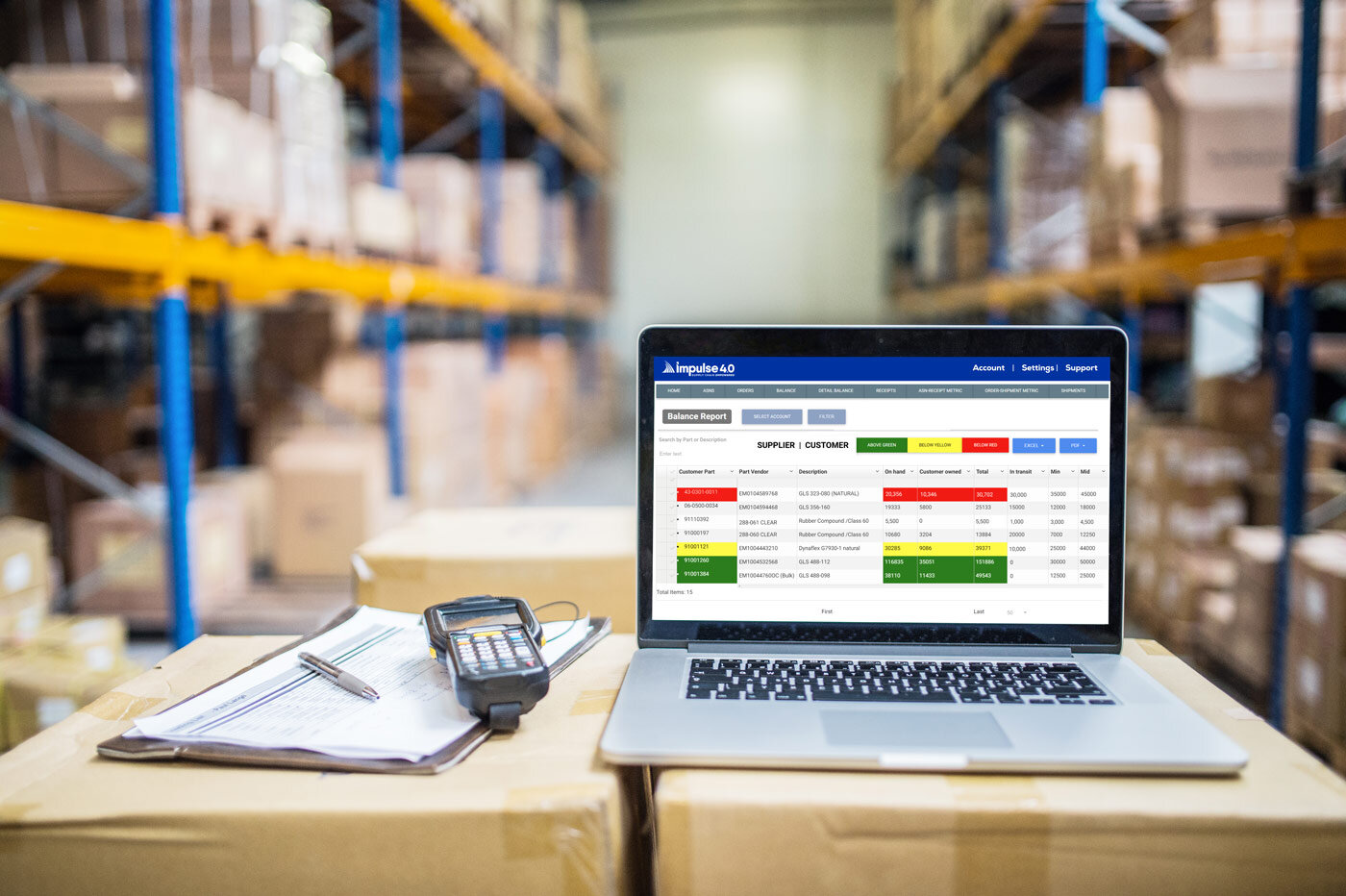

We have invested heavily in having state of the art and user-friendly online tools for planning, production, inventory, and transaction reporting. Our vision for our customers is an all-digital connected landscape, in full compliance of AIAG / VDA traceability and with the high efficiency and accuracy brought by end-to-end visibility and tracking.

Our in-house capability to work through the most challenging IT problems, combined with our deep expertise in supply chain management, allows us to make this vision a reality.

Friendly to All

We have developed custom integrations with all the leading ERPs used in the manufacturing industry. Our SAP/EDI-Friendly proprietary IT system reduces the time and effort to exchange data to reflect each handshake along the complete supply chain all the way from the supplier shipment to the production line delivery point.

We will work with your IT team as far as they will allow to develop real-time and/or scheduled inventory match-up reports, ordering integrations, and receipt PO automation solutions.

4.0 Visibility

The combination of barcode labeled materials with Advanced Shipping Notifications (ASN’s) allows for easier compliance, faster processing, and streamlined flow visible to all parties. Our system makes the following information available to you and your suppliers via real-time online access or automatically scheduled reports and notifications.

In-transit inventory and ETA controls

On-hand Inventory (plant owned and supplier owned)

Quarantine, Blocked material

Min/Mid/Max Levels with alerts

Aging

Transaction history

Deliveries

4.0 Traceability

Traceability provides the backbone for efficiency and accountability. Our standard operating procedure and IT systems are based on the automotive and medical models of end-to-end digital traceability.

We apply barcode labeling processes tied with Advance Shipment Notices (ASN) at each handshake starting with the supplier’s shipment all the way to the final delivery point, be it at the plant’s door or production line.

This combination improves issues related to a shipment’s qualitative accuracy, quantitative audits, and timeliness. Having all this information from the beginning, allows us to correlate any data from a specific shipment to help improve other areas of the supply chain, such as accounts payable.

Always Innovating

Our R&D team is constantly pushing the envelope and experimenting with new technologies that can be applied to your supply chain. We have been working with block-chain since 2017, are RFID ready, and have experimented with augmented reality vision in the warehouse.

Our continual investment into 4.0 tools that enhance relationships and provide real time transparency creates the right atmosphere for an environment of innovation and collaboration.